With two food grade facilities and many different unit operations, AVEKA is well equipped to handle your food, beverage and nutraceutical needs. With pre- and post-processing options, AVEKA is your one-stop shop for all your liquid, powder and particle needs. Our expansive understanding of food quality and safety regulations will help swiftly bring your project to the next stage.

Featured Projects

Hammer Milling a Food-Grade Material

Learn More

Dry Blending a Kosher Food Product

Learn More

Scaling Up a Food Grade Product Using Fluid Bed Drying

Learn More

Liquid Blending for a Vitamin Formula Application

Learn More

Washing and Decanting to Increase Protein Content of a Plant-Based Flour

Learn More

Characterization of Flavor Powders

Learn More

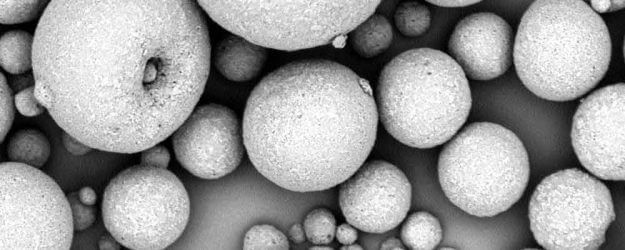

Spray Drying Highly-Engineered Particles

Learn More

Repackaging a Food-Grade Material

Learn More

Certificates

OK Kosher

OK Kosher  Kosher OU

Kosher OU  ISA Halal

ISA Halal  Organic Certified by QAI

Organic Certified by QAI  FSSC 22000

FSSC 22000  State of Iowa FDA Food Grade Processor

State of Iowa FDA Food Grade Processor  USDA - FSIS Inspected

USDA - FSIS Inspected  HACCP

HACCP  FAMI-QS

FAMI-QS