What are Engineered Particles?

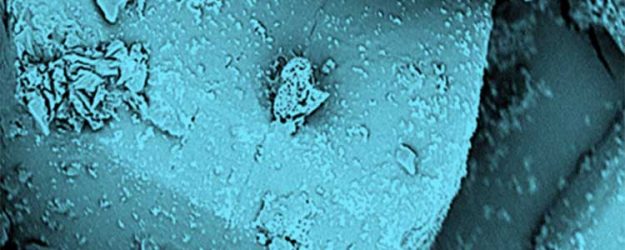

When specific particle attributes are desired, but are not easily obtained, engineering the particles might be the solution. For example, particles could be engineered to surround materials (liquid or solid) with a coating. Engineered particles could also have a distinct core and shell (like an egg) or have a homogeneous matrix structure (like a blueberry muffin). The coating could be rigid or soft, impervious or porous, complete or partial. There are many methods and technologies that are employed to encapsulate a variety of materials, each method providing unique advantages to the final particle. AVEKA‘s particle engineering methods include spray drying, dry water, alginate beads, magnetically assisted impact coating (MAIC), polyoxymethylene urea (PMU), prilling, and tablet coating. The technique is selected based on materials, desired end size, release mechanism and active ingredient. AVEKA‘s R&D and production teams will work with you to design a particle specific for your needs.