Spray Drying Services

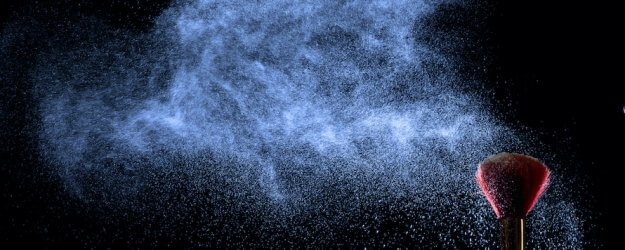

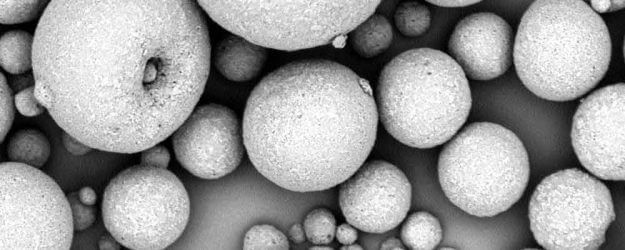

Spray drying is a continuous process used to manufacture free-flowing dry powders from a liquid feedstock. The liquid feedstock is atomized into a heated air stream where the droplets rapidly dry to form individual particles. Particle size, morphology and moisture content can be controlled by adjusting dryer parameters, nozzle configuration and feed properties. Spray drying is widely used across many industries and can efficiently dry commodity material as well as create value-added, designer particles.

AVEKA utilizes both tower and horizontal box dryers equipped with two-fluid and hydraulic spray nozzles to process a variety of aqueous systems. Extensive pre- and post-processing capabilities contribute to the turnkey experience AVEKA provides.