Jet Milling Services

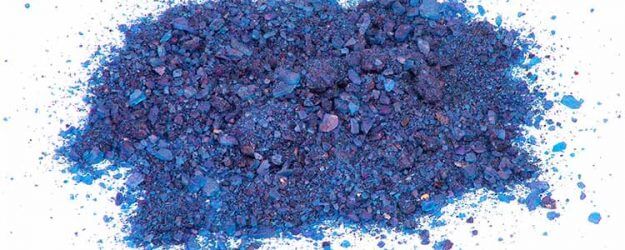

Do you need to reduce your materials to a fine particle size?

Our Fluidized Bed Jet Mill, also known as an Air Classifying Mill, combines dense phase micronization using turbulent-free jets with high-efficiency centrifugal air classification in a high-energy processing zone.

This allows for enhanced comminution through particle-on-particle impact and optimized particle dispersion. Resulting in improved separation and lower overall energy consumption.

Jet Milling is an efficient way to mill or micronize various ceramics, polymers, and other friable materials. Abrasive and temperature-sensitive products can be finely ground with minimum contamination.

The simple, easy-to-clean, cost-effective design offers precise top-size control with a narrow size distribution. Some materials can be as low as 95% < 5 um size range.

OPERATING PRINCIPLE:

The raw material feed is introduced into the processing zone. Load cells control mill loading for optimum grinding efficiency and/or product size distribution control.

Turbulent-free jets are fluidizing the particles in the milling zone. The impact of the particles causes them to break and reduce in size. Particles that have been sufficiently reduced in size will leave the processing zone through the centrifugal classifier. The classifier rotor speed will define the ultimate particle size.

Rotor speed, air pressure, and filling level in the processing zone optimize productivity, product size, and distribution shape.

AVEKA maintains lab facilities for product testing, equipment evaluation and custom processing.

Learn more about how we can meet your milling needs.