Is your business considering purchasing precision jet milling equipment for fine particle size reduction and increased throughput? Whether you’ve been toll manufacturing your materials for years or have a new product that you’d like to produce entirely on-site, you’ve come to the right place.

At AVEKA CCE Technologies, we design, build, and sell custom Fluidized Bed Jet Mills for your milling needs. Here is our complete guide with everything you need to know about purchasing a jet mill specific to your needs.

What is jet milling?

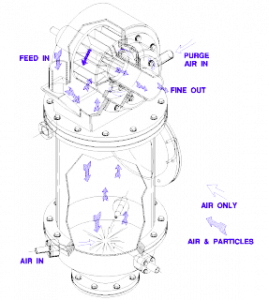

Jet milling incorporates dense phase micronization using turbulent, free jets in combination with high efficiency centrifugal air classification within a common housing. This combination allows for enhanced comminution by high probability particle-on-particle impact for breakage and a high degree of particle dispersion for improved separation.

How does the process work?

The raw material feed is introduced into the common housing through either a double flapper valve or an injector. Mill load is then formed by flooding the pulverizing zone to a level above the grinding nozzles.

Turbulent, free jets are used to accelerate the particles for impact and breakage. After impact, the fluid and size-reduced particles leave the bed and travel upwards to the centrifugal classifier.

There, the rotor speed will define what size will continue with the fluid through the rotor and which will be rejected back to the particle bed for further size reduction. The high degree of particle dispersion leaving the pulverizing zone aids in the efficient removal of fine particles by the classifier.

4 reasons to consider in-house jet milling

While AVEKA would much prefer to toll manufacture your particles for you, there are several good cases for why a business would want to jet mill their own materials. Here are the four most common reasons to do it yourself.

1. Your shipping costs are too high

If the cost of shipping your materials to and from a processing facility is cutting into your product margins too much, you may want to consider investing in a jet milling setup of your own. This is especially true if your operations are nowhere near a processing facility or your materials require special (and costly) handling instructions.

2. You’re producing a high volume of material

If you’re fortunate enough that your product is in high demand and constantly in production, then the better long-term financial option may be to mill your materials entirely or partially in-house. While it likely won’t be cost-effective to run small batches at irregular intervals, regular full-scale production would certainly warrant an equipment purchase.

3. You require a faster turnaround

If you simply cannot wait for your material to be processed and shipped (or don’t have the warehouse space to store it in bulk), then you may want to consider milling it at your own facility. Many businesses rely on time-sensitive or made-to-order purchases which would greatly benefit from cutting out the middleman.

4. You have the space, capital, and qualified personnel to do it yourself

The final reason to consider jet milling in-house is – quite simply – because you can. If you have ample room in your facility to fit the equipment, enough capital to make the investment, and the dedicated staff members to operate it, then it’s definitely an internal discussion you should have with your team.

What industries is jet milling geared toward?

Jet milling is an ideal choice for a wide variety of industries, including but not limited to:

What materials work best for jet milling?

Jet milling works great with most ceramics, glass, abrasives, minerals, and polymers, particularly those used in 3D printing applications. It is also an ideal process for toners, powder coatings, and other fine powder applications. If you’re unsure whether or not your particular feed will be a good fit, here are some material properties to consider.

Good candidates:

- Dense materials

- Hard materials

- Abrasive materials

- Brittle materials

- Friable materials

- Materials that respond to impact with crack propagation

Poor candidates:

- Wet materials

- Sticky or entangled materials

- Elastic materials

- Deforming materials

- Light and/or fluffy materials

- Materials that absorb impact or are difficult to accelerate

Predicting whether a material will respond to jet milling successfully can be difficult and often surprising, so it is always worth a feasibility trial to find out. Contact AVEKA today to schedule your material test batch.

Other important material factors to consider

What is the particle size of my feed material?

Feed material greater than 1/4” cannot be directly handled by a fluid bed jet mill. An additional pre-milling option would first be required, such as hammer milling, roller crushing, or jaw crushing.

What is my target particle size?

AVEKA CCE’s Fluidized Bed Jet Mills are able to achieve particle sizes as fine as 1 micron with some materials. However, size distributions typically fall somewhere in the 5–70 μm range.

Is my material a combustible powder?

If you plan to work with a combustible powder, you need to ensure that your jet mill has the necessary suppression systems in place. AVEKA can customize any of our models to include explosion suppression systems (see image).

Is my material abrasive?

Jet mills are very effective at milling abrasive materials with minimized wear. This is because the system utilizes particle-on-particle impact and is built primarily with wear-resistant surfaces and components.

What are the benefits of using a fluid bed jet mill?

There are many reasons to choose jet milling over other common forms of milling, such as cryogenic milling, hammer milling, and jaw crushing. Here are five that we feel are particularly worth noting:

- Low maintenance and easy to clean

- Increased control over load cell and top size

- Achieve narrower product size distributions

- Lower overall energy consumption

- Wear-resistant construction (abrasive-resistant linings, wear-resistant coatings, a polyurethane mill body, a tungsten carbide plasma-coated classifier rotor, etc.)

How do I choose the right model for my needs?

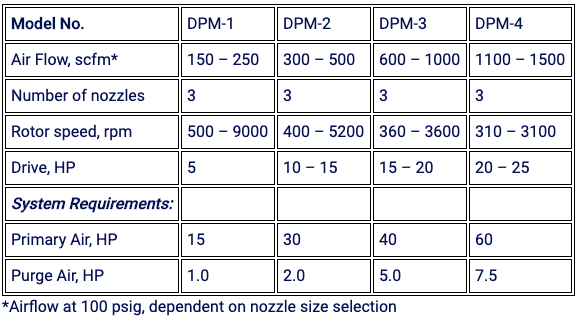

AVEKA CCE Technologies offers four distinct models of Fluidized Bed Jet Mills to choose from. See the chart below to compare their base specifications and system requirements.

AVEKA CCE also offers a lab-scale jet mill. The Model 20 Opposed-Jet Lab Pulverizer is designed to be used in closed circuit with the Model 100 Classifier for the production of dry powders in lab size quantities at rates of up to 4.5 kg/hr. This closed circuit combines the particle-to-particle impact of opposed jet fluid energy milling with high efficiency classification, resulting in the production of steep distributions with close top size control. This combination allows the user to expand the versatility of the lab classifier in the production of small quantity, narrow distribution products with minimum equipment adjustment.

Contact the experts at AVEKA so we can help you determine the right jet mill(s) for your needs. We are also able to customize any of these models to better suit your specific requirements.

What steps are involved when purchasing jet milling equipment?

After you’ve reached out to an AVEKA representative to discuss your project/operation, these are the typical steps involved in the process of making a purchase:

1. Gather initial product/material information

2. Perform a trial run to determine feasibility and throughput needs (recommended)

3. Obtain a budgetary quote and initial purchase order

4. Work with our engineers to determine the exact specifications needed for your system

5. Obtain a finalized quote and purchase order

6. System is custom-built per specification

What will my jet mill system include?

All AVEKA CCE Technologies Fluidized Bed Jet Mill Systems come complete with:

- A mill

- A flow source

- A product cyclone and/or collector

- A feed system

- A control package

While all of our jet mills are designed with wear in mind, we do also sell any and all replacement parts should you need them.

What kind of warranty and support can I expect?

At AVEKA CCE Technologies, we offer a 1-year warranty on all of our jet mill models. In addition, once your system is built, shipped to your facility, and installed, one of our engineers will make a site visit to check that everything is operating correctly and make any necessary adjustments. We also offer startup assistance and training so that your operators are comfortable and confident with the new system before production begins.

Where can I go to learn more and purchase a jet mill for my business?

AVEKA CCE Technologies will work closely with you to understand your needs and which model(s) best fits your application. Our engineers will work with you every step of the way to customize a system to fit well within your process and bring incredible value to your project. Ensure your needs are met with the precision equipment that AVEKA CCE offers. Call us today to custom build your new Fluidized Bed Jet Mill.