Process

Liquid Blending Services

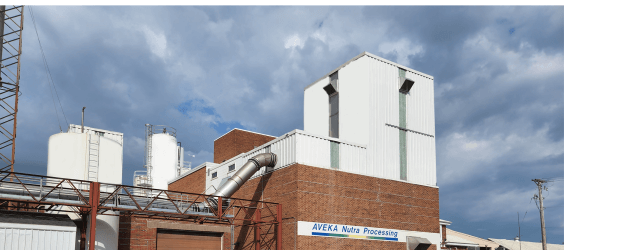

AVEKA has a wide range of liquid tanks available to meet your tolling needs. We offer high-shear mixing, temperature control, and automated HMI process systems.

Learn how we can create your customized product.

Capabilities and Equipment Specs

Factors to Consider

Featured Projects

Industries

Locations