What is Vibratory Screening?

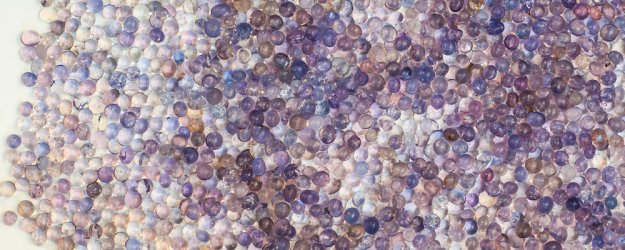

Vibratory screening, or mechanical screening, is the process of taking particulate material and separating it into multiple grades by particle size. This method of particle separation uses gravity, motion and mesh screens or sieves to accomplish the separation. The screener is mechanically vibrated in a controlled manner to allow the particles to flow across the screen and outward in a spiral pattern. The oversize particles flow across the screen and are discharged through a spout. The smaller particles fall through the mesh screen(s) and continue to spiral until they are discharged. A series of screens can be set up to allow for multiple size classifications in one pass.

AVEKA has several sizes and models of vibratory screeners used to classify a broad range of dry materials including polymers, pigments, oxides, inorganics, organics, feed and food. In addition, AVEKA has ultrasonic screeners available that more efficiently classify low density materials.