The Challenge:

AVEKA was approached by a customer to process rough, jagged particles into smooth, more spherical particles to ease downstream use and flowability. Due to several characteristics, including molecular weight and melt viscosity, AVEKA determined this material did not easily form the desired spheres when spray chilled/prilled.

AVEKA Solution:

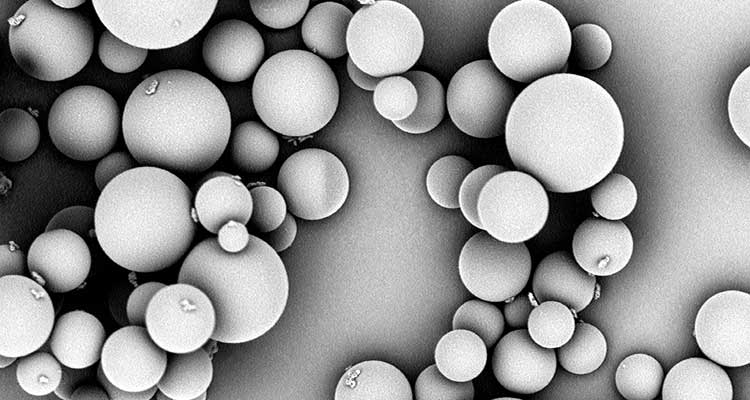

AVEKA suggested surface modification using spheroidization to modify the customer’s material. To achieve the desired particle morphology, AVEKA performed multiple trials and optimized temperatures, spray angle, air flow rates, feed rate and nozzle configurations. AVEKA used laser light scattering to measure particle size distribution and performed scanning electron microcsopy (SEM) and digital image processing to image and quantify particle morphology. The final product was more spherical and demonstrated greatly improved powder flowability, which met the customer’s downstream processing needs.