The Challenge:

AVEKA’s technical team was asked to change the flow properties of a particle. Fumed silica is typically added to a material in order to make the material flow better. The problem with just blending fumed silica with a material is that it settles out during shipping or with minimal force.

AVEKA Solution:

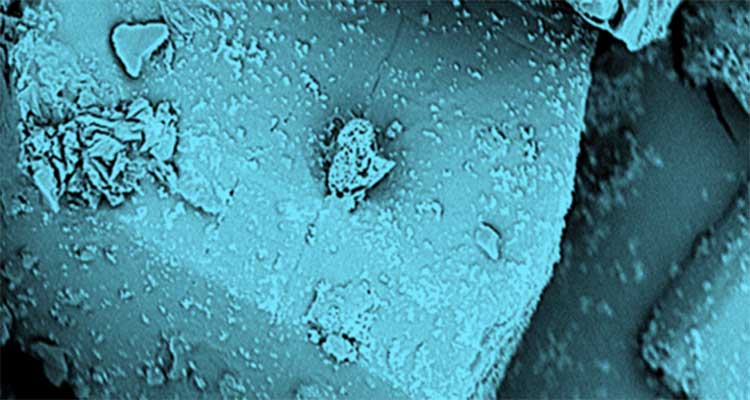

In order to provide flowability, AVEKA used its patented MAIC (Magnetically Assisted Impact Coating) technology to impact and bind the fumed silica onto the surface of the material. Attaching the fumed silica to the material rather than merely mixing it in resulted in two notable improvements:

- Significant reduction in the amount of silica needed.

- A resulting material that is stable to shaking and transportation.